HomeProductTension systemTension sensor

Tension sensor BK series

Application Description:

"Anyou" BK-4A series tension sensor adopts cross-shear beam structure and integrally sealed and anti-corrosion design, which makes the sensor output linear, fast response, anti-corrosion and dust-proof, high stability, durable . Foil strain gauges provide high sensitivity at low tensions without the need for a built-in temperature compensation network. Widely used in various industrial production lines.

Hotline:021-60892191 Message

- Product description

- Performance parameter

- Installation drawings

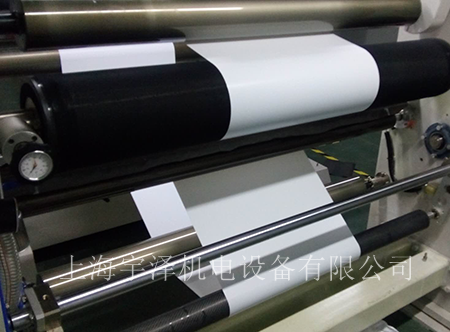

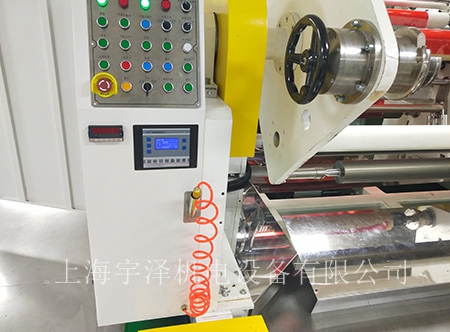

- Application site

- Download

"Anyou" BK-4A series tension sensor adopts cross-shear beam structure and integrally sealed and anti-corrosion design, which makes the sensor output linear, fast response, anti-corrosion and dust-proof, high stability, durable . Foil strain gauges provide high sensitivity at low tensions without the need for a built-in temperature compensation network. Widely used in various industrial production lines.

The main features are as follows:

The main features are as follows:

● High response frequency of output signal

● Good linearity of output signal

● Strong ability to resist overload and partial load

● Built-in temperature compensation network, small temperature drift

● Same high sensitivity to high and low tension

● Wide effective detection range, up to 45: 1

● Special process is adopted to ensure high bonding strength between strain gauge and substrate

● Industrial dust and corrosion protection process design

● Using special alloy, durable

| Rated load(N) | |

| BK-4A | 200050001000020000300005000060000 |

| 100000(Can be customized according to user requirements) | |

| Working power | DC5-15V |

| Tension signal output | 0-20mV/0-250mV |

| 输出灵敏度 | 1.5-2mV/V |

| Operating temperature | -38℃~+75℃ |

| Working humidity | <90%R.H. |

| Sensor form | Resistance strain gauge |

| Linear error | <±0.1% |

| Repeatability error | <±0.1% |

| Comprehensive error | <±0.2% |

| Temperature drift | <±0.02%/℃ |

| Sensor material | Special alloy |

Manual.pdf

Recommended News

-

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26