HomeProductTension systemExplosion proof products

Tension sensor UPB series

Application Description:

The UPB series bearing seat type tension sensor adopts advanced sensor technology and an integral fully sealed anti-corrosion design, which ensures good output linearity, fast response speed, corrosion and dust prevention, high stability, and durability.

- Product description

- Performance parameter

- Installation drawings

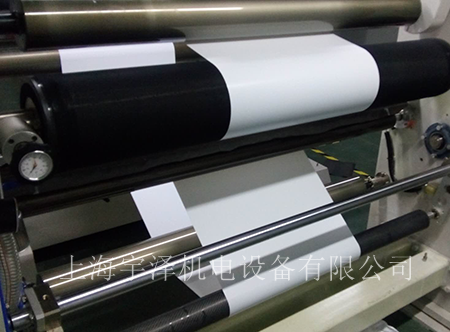

- Application site

- Download

The UPB series bearing seat type tension sensor adopts advanced sensor technology and an integral fully sealed anti-corrosion design, which ensures good output linearity, fast response speed, corrosion and dust prevention, high stability, and durability. The foil type strain gauge can still provide high sensitivity under low tension. Widely used in printing, lamination, coating, die-cutting, papermaking, rubber, textile, steel strip, wire and cable, film and other coiling control equipment and production lines.

产品特点

● 输出信号响应频率高、线性度好

● 内置温度补偿网络,温度漂移小

● 对高低张力具有同样的高灵敏度

● 张力有效检测范围宽,高达45:1

● 理想过载能力可达1000%

● 轴承座下安装,无活动部件

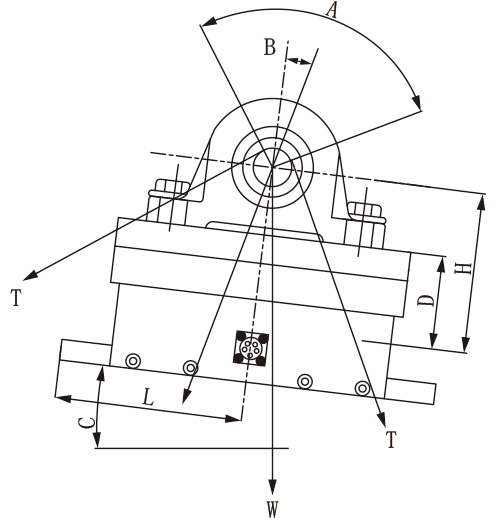

额定载荷的计算和选择

MWF*={[2TXKXSIN (A/ 2)X(HsinB+LcosB)土W(LcosC-HcosC)}**/(2L)MWF:理想工作压力(N) ;

A:包角(度) ;B: 张力角(度);

K:安全系数(1.4-2.0) ;T: 理想总张力(N) ;W:张力辊自重(N) ;

*MWF计算结果是单个传感器所承受的理想工作压力

**B角如果在水平线下,用"+", 如果在水平线上用'”_ "

| 工作电源 | DC5-15V |

| 张力信号输出 | 0-20mV |

| 工作温度 | - 38°C ~+ 75C |

| 工作湿度 | <90%R.H. |

| 传感器形式 | 电阻应变式 |

| 线性误差 | <土0.1% |

| 重复性误差 | <+0.1 % |

| 综合误差 | <土0.2% |

| 温度漂移 | <土0.02%/°C |

| 接头规格 | 航空WS-12 |

| 传感器材料 | 特种合 |

| 传感器外壳材料 | 金合金钢 |

| 防护等级 | IP65 |

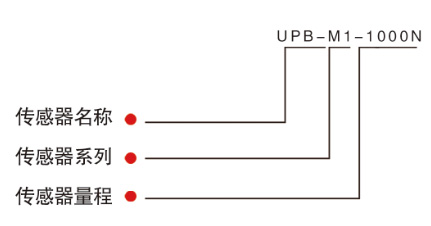

订货代码(例如)

产品选型表

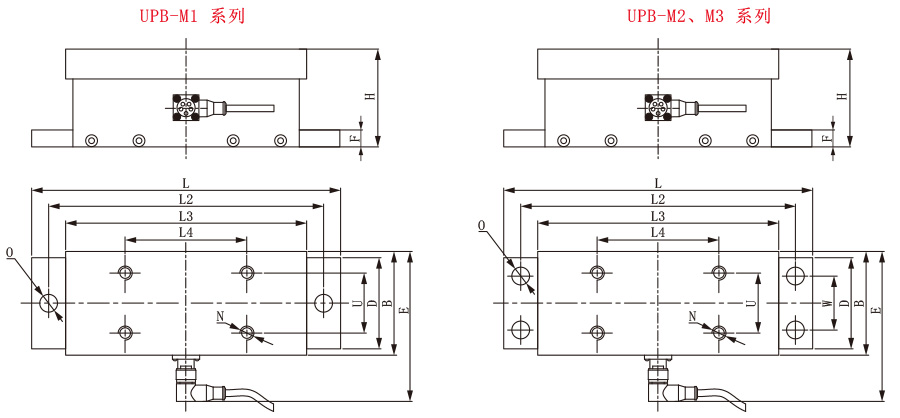

| 型号 | 额定载荷(N) | 外 形 尺 寸 | ||||||||||||

| L | B | H | D | E | F | G | H | N | O | U | V | W | ||

| UPB-M3 | 80000N | 400 | 72 | 149 | 108 | 87 | 30 | 360 | 300 | — | 18 | — | — | 70 |

| 100000N | 400 | 72 | 149 | 108 | 87 | 30 | 360 | 300 | — | 18 | — | — | 70 | |

| 可根据客户要求定制 | ||||||||||||||

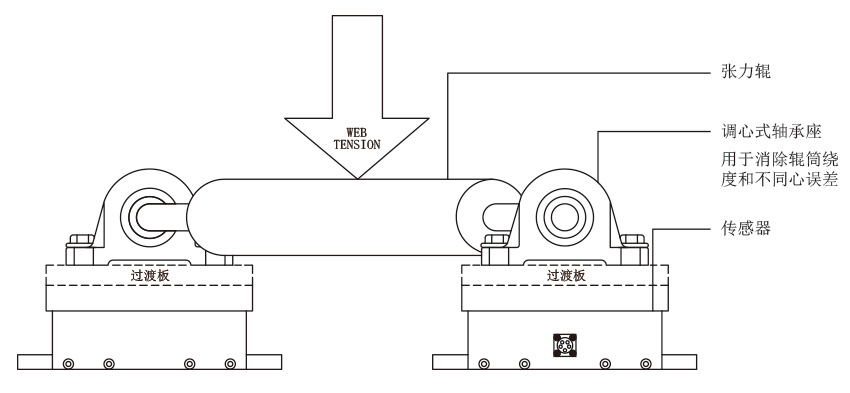

Installation method

The UPB series sensors are installed on the bearing seat using a tension roller mounted on a separate shaft table. The bearing seat is connected to the sensor through a transition plate.

Manual.pdf

CAD.dwg

Recommended News

-

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26 -

Four main points of maintenance of the correction system

2019-12-26